Home | Baking stoves

Wood-burning baking stoves and pizza domes

Freshly baked from a fireclay

wood-burning baking stove …

… crunchy & simply delicious!

The best baking results are achieved from baking on fireclay:

Baking on fireclay is one of the oldest methods – and still one of the most popular. And rightly so! Fireclay has a high degree of porosity. The stone therefore absorbs moisture and then releases it back into the baked goods. This ensures a crispy crust and a soft but dense centre – a dream! Baking stoves made of fireclay are therefore frequently used for commercial purposes in the catering industry (especially pizza stoves). But the dream of an outdoor baking stove can also be fulfilled privately – for example with our baking stove sets.

Your advantages

Tongue and groove connection

Thanks to the tongue & groove joints, uncomplicated assembly and short construction times are guaranteed. Nevertheless, you retain the greatest level of flexibility. Our baking stoves can be individually adapted to your needs and wishes. The size as well as the design of the outer shell is up to you.

Baking chamber ergonomics

The baking chamber geometry of our baking stoves is well thought out. The fireclay stores the heat and radiates it inwards after a certain period of time. The best baking results are achieved when the basement plate is heated up correctly as well. Our high-quality fireclay defies the frequent temperature changes over a long service life.

FAQs

Frequently asked questions about our fireclay baking stoves

On the one hand, of course, because the wood provides a very special aroma, but also because there is a different baking chamber climate in wood-burning baking stoves.

While the heat in an electric oven is mainly transferred to the baked goods via the air, i.e. by means of convection heat, in a wood-burning stove this happens primarily via radiant heat.

Fireclay also has a high degree of porosity. The stone therefore absorbs moisture and then releases it back into the baked goods. This ensures a crispy crust and a soft center.

Wood-burning baking stoves are traditionally used to bake stone-oven pizza or stone-oven bread. But it can also be used to prepare tarte flambée, pastries, cakes, roasts, barbecue skewers, casseroles, fish and much more.

The special thing about a wood-burning baking stove made of fireclay: once heated, it retains the heat for a very long time due to its high heat storage capacity. This means you can start with the dishes that need the most heat, such as pizzas, then breads and meat, and then cakes. The remaining heat is ideal for drying fruit.

This depends on how the baking stove is to be used for the most part. This is because every dish has its own requirements in terms of temperature, time and baking chamber climate, which a suitable baking stove design can meet. In general, there are two operating modes for baking stoves: “heat saving baking stoves” and “constantly fired” baking stoves.

In a “heat saving baking stove”, the energy is stored for a long time in the fireclay bricks of the baking chamber, so that food can be prepared for several hours at a slightly decreasing temperature. This operating mode is perfect for baking bread.

For preparing pizzas and tarte flambée, on the other hand, “constantly fired” baking stoves are ideal. Here, after burning a large amount of firewood, the baking stove is further heated by permanently adding small quantities of firewood, usually in the rear or edge area of the baking chamber. These baking stoves therefore reach high temperatures of > 300 °C over a long period of time.

In addition to the design / operating mode, there are also differences in the geometry, i.e. the shape of the baking stove. This is further explained in the next section.

In addition to the design / operating mode, baking stoves also differ in their geometry, i.e. the shape of the baking chamber. Rectangular, tunnel, dome or bulb – there are many options here. What is most suitable also depends on how the baking stove is to be used.

If the baking stove is to be used for baking bread, the classic heat saving baking stove with a tunnel vault (roll shape) is recommended. Thanks to the even heat distribution in the baking chamber, the loaves of bread do not need to be turned and repositioned during the baking process. These baking stoves are often built with a low baking chamber height of just 25 cm. This optimizes heat transfer and reduces fuel consumption.

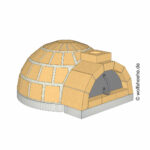

The dome vault, on the other hand, is suitable for continuously fired pizza baking stoves. The burnout opening is located in the front area above the entrance of the pizza dome. The hot combustion gases can pass the high vault and thus maintain high temperatures.

You will find baking stoves of various shapes and sizes in our comprehensive range of baking stoves. This means that there is a suitable model for every application.

If you are looking for a tunnel baking stove, we recommend our REMUS. It is also available as a double-decker, the so-called REMUS Duo. Both models, REMUS and REMUS Duo, can flexibly be extended thanks to the extension kit. They can therefore be used in the private sector, but also in the catering industry. For particularly large baking stoves – e.g. for caterers, village communities and clubs – we offer our COMMUNIS planning aids for tunnel baking stoves.

If you are looking for a pizza dome, take a look at our ITALICUS. The ITALICUS sets consist of practical vault bricks that enable a quick and material-saving construction. Craft skills are required here.

A wood-burning baking stove in the backyard generally does not require a permit, unless you want to build a “walk-in” bakery. A building permit must then be obtained from the local building authority and the chimney sweep must be informed for approval. However, the regulations vary significantly depending on the country, federal state and district. It is therefore best to contact the responsible building authority and the responsible chimney sweep beforehand and ask which regional laws and permits must be complied with.

On the one hand, of course, because the wood provides a very special aroma, but also because there is a different baking chamber climate in wood-burning baking stoves.

While the heat in an electric oven is mainly transferred to the baked goods via the air, i.e. by means of convection heat, in a wood-burning stove this happens primarily via radiant heat.

Fireclay also has a high degree of porosity. The stone therefore absorbs moisture and then releases it back into the baked goods. This ensures a crispy crust and a soft center.

Wood-burning baking stoves are traditionally used to bake stone-oven pizza or stone-oven bread. But it can also be used to prepare tarte flambée, pastries, cakes, roasts, barbecue skewers, casseroles, fish and much more.

The special thing about a wood-burning baking stove made of fireclay: once heated, it retains the heat for a very long time due to its high heat storage capacity. This means you can start with the dishes that need the most heat, such as pizzas, then breads and meat, and then cakes. The remaining heat is ideal for drying fruit.

This depends on how the baking stove is to be used for the most part. This is because every dish has its own requirements in terms of temperature, time and baking chamber climate, which a suitable baking stove design can meet. In general, there are two operating modes for baking stoves: “heat saving baking stoves” and “constantly fired” baking stoves.

In a “heat saving baking stove”, the energy is stored for a long time in the fireclay bricks of the baking chamber, so that food can be prepared for several hours at a slightly decreasing temperature. This operating mode is perfect for baking bread.

For preparing pizzas and tarte flambée, on the other hand, “constantly fired” baking stoves are ideal. Here, after burning a large amount of firewood, the baking stove is further heated by permanently adding small quantities of firewood, usually in the rear or edge area of the baking chamber. These baking stoves therefore reach high temperatures of > 300 °C over a long period of time.

In addition to the design / operating mode, there are also differences in the geometry, i.e. the shape of the baking stove. This is further explained in the next section.

In addition to the design / operating mode, baking stoves also differ in their geometry, i.e. the shape of the baking chamber. Rectangular, tunnel, dome or bulb – there are many options here. What is most suitable also depends on how the baking stove is to be used.

If the baking stove is to be used for baking bread, the classic heat saving baking stove with a tunnel vault (roll shape) is recommended. Thanks to the even heat distribution in the baking chamber, the loaves of bread do not need to be turned and repositioned during the baking process. These baking stoves are often built with a low baking chamber height of just 25 cm. This optimizes heat transfer and reduces fuel consumption.

The dome vault, on the other hand, is suitable for continuously fired pizza baking stoves. The burnout opening is located in the front area above the entrance of the pizza dome. The hot combustion gases can pass the high vault and thus maintain high temperatures.

You will find baking stoves of various shapes and sizes in our comprehensive range of baking stoves. This means that there is a suitable model for every application.

If you are looking for a tunnel baking stove, we recommend our REMUS. It is also available as a double-decker, the so-called REMUS Duo. Both models, REMUS and REMUS Duo, can flexibly be extended thanks to the extension kit. They can therefore be used in the private sector, but also in the catering industry. For particularly large baking stoves – e.g. for caterers, village communities and clubs – we offer our COMMUNIS planning aids for tunnel baking stoves.

If you are looking for a pizza dome, take a look at our ITALICUS. The ITALICUS sets consist of practical vault bricks that enable a quick and material-saving construction. Craft skills are required here.

A wood-burning baking stove in the backyard generally does not require a permit, unless you want to build a “walk-in” bakery. A building permit must then be obtained from the local building authority and the chimney sweep must be informed for approval. However, the regulations vary significantly depending on the country, federal state and district. It is therefore best to contact the responsible building authority and the responsible chimney sweep beforehand and ask which regional laws and permits must be complied with.