Your required size

Calculated dimensions

Diameter dome inside: 0 cm

Height dome inside: 0 cm

Wall thickness opening: 0 cm

Wall thickness dome: 0 cm

Width opening: 0 cm

Height opening: 0 cm

Diameter smoke outlet: 0 cm

Insulation area: 0m2

Required material

Item number 708076

0 kg

(0 bags of 20 kg)

0 piece

(Total: 0 kg )

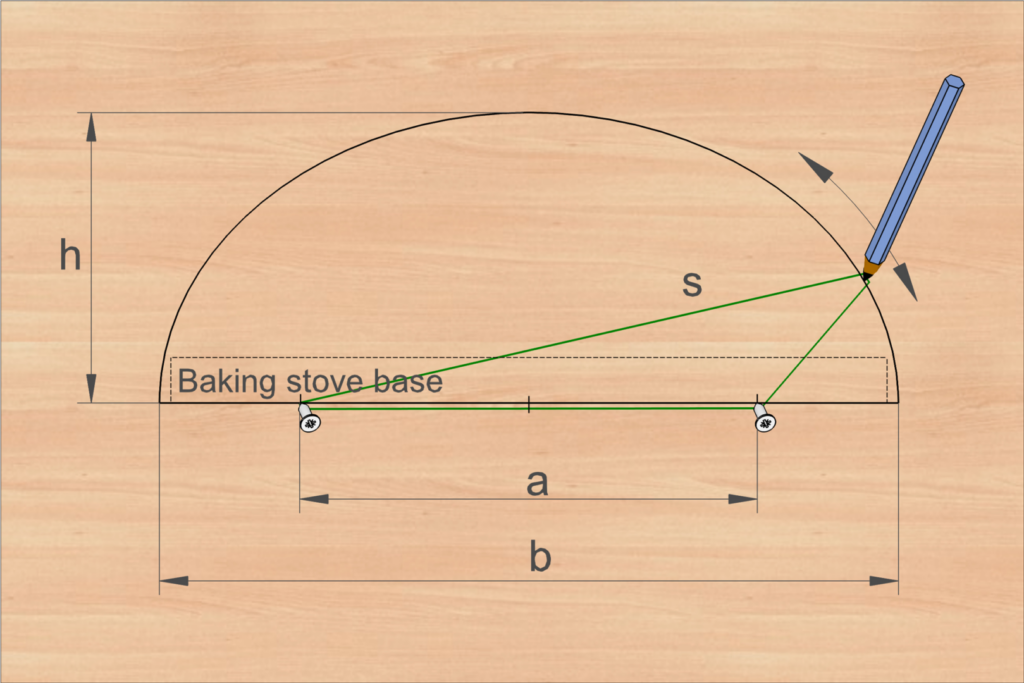

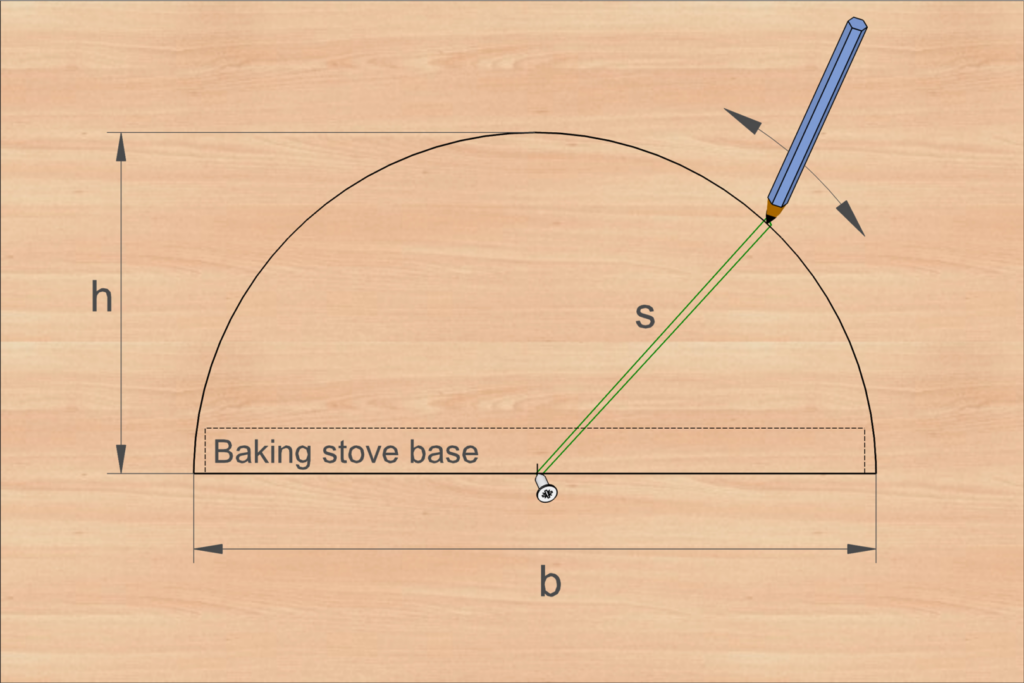

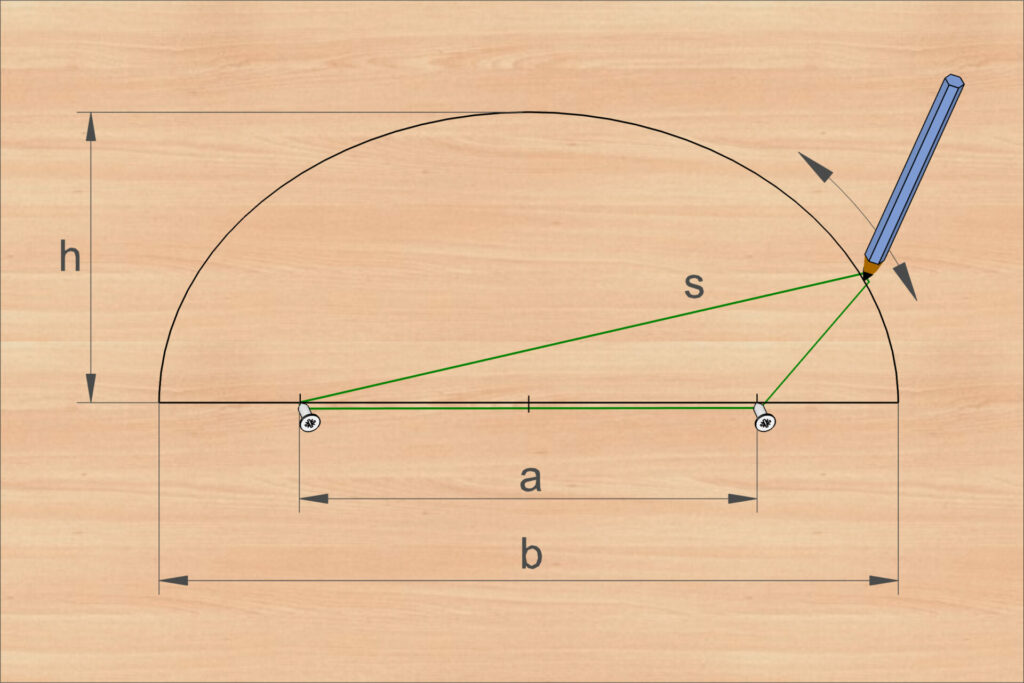

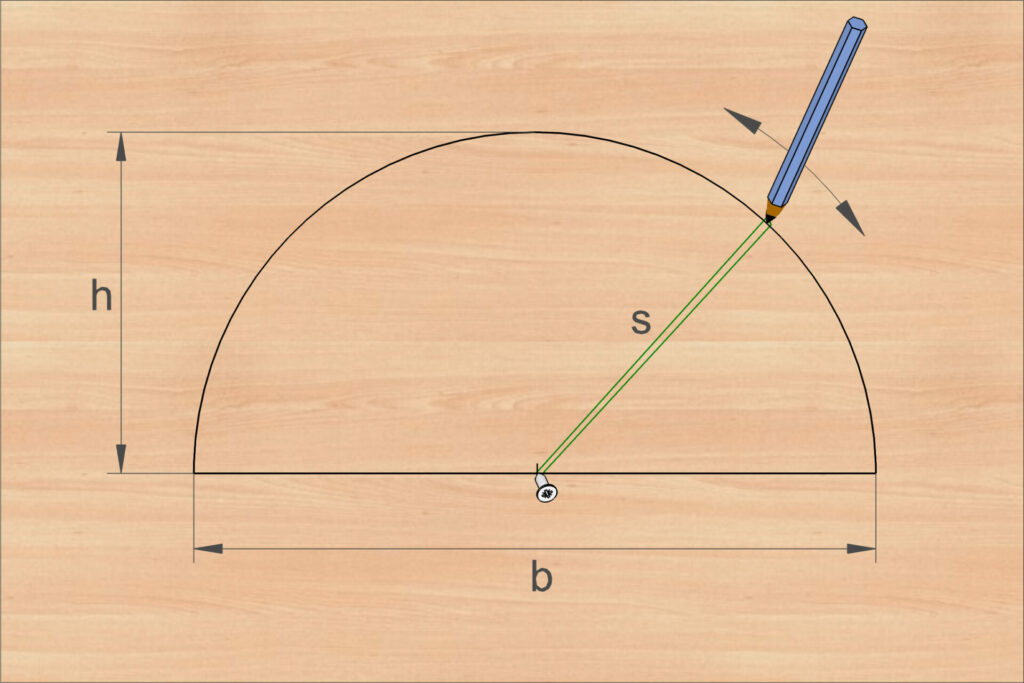

Stencil dome inside

Height (h): 0 cm

Width (w): 0 cm

Distance combustion point (a): 0 cm

Cord length (s): 0 cm

Stencil dome outside

Height (h): 0 cm

Width (w): 0 cm

Distance combustion points (a): 0 cm

Cord length (s): 0 cm

Instructions: And this is how it works...

A pizza dome made of refractory concrete

Click here for the video instructions:

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information

Why is pizza best made in a pizza dome?

The perfect pizza should be baked at high temperatures, as quickly and evenly as possible – and this can perfectly be realized with a wood-burning pizza dome. The fire has a lot of space upwards and can therefore develop high temperatures. The round shape allows the heat to flow evenly around the baked goods.

Not only restaurants and professional chefs, but also private pizza lovers want a pizza stove like this. We will show you how you can build a complete pizza dome made of refractory concrete, also known as refractory cement or refractory mortar, and offer your customers a relatively simple and high-quality alternative to a baking stove made of stone – at an attractive price.

For which pizza domes is refractory concrete suitable?

Traditionally, the construction of a pizza dome is made of fireclay bricks. We offer prefabricated vault bricks with slight angles on the sides for this purpose. However, smaller models can also be built from refractory concrete, which we also have in our range.

Our refractory concrete consists mainly of fireclay. Its technical properties are therefore very similar: it has an application temperature of up to 1,100 °C and consistent flexural strength and compressive strength up to high temperatures.

The baking stove made of refractory concrete is therefore a high-quality and durable solution. Of course, it is also food-safe.

How do I use refractory concrete?

Our refractory concrete is very versatile: it can be processed both as a liquid casting compound and as a mouldable ramming mixture. To use the refractory concrete as a mouldable ramming mixture, it is mixed with slightly less water (0.2 l / kg), to use it for mold casting, with more water (0.24 l / kg).

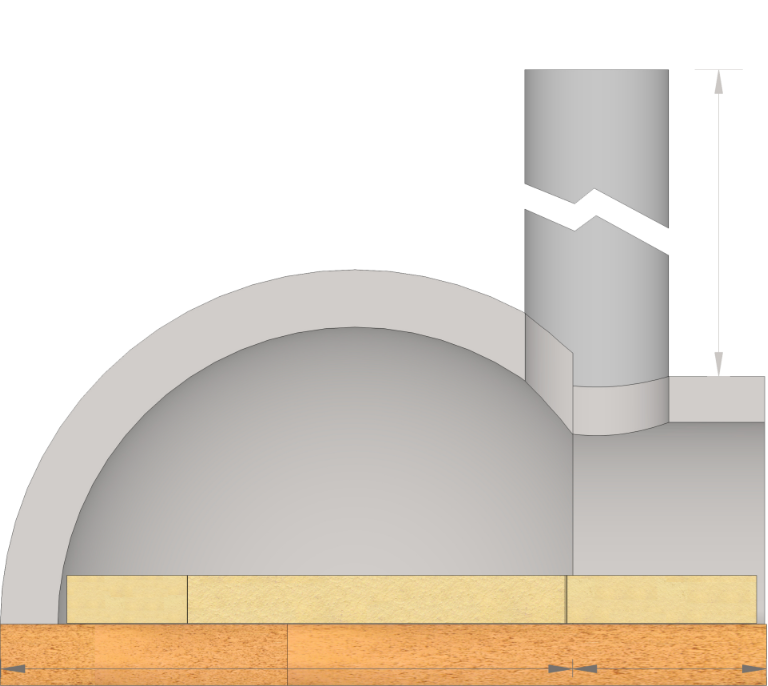

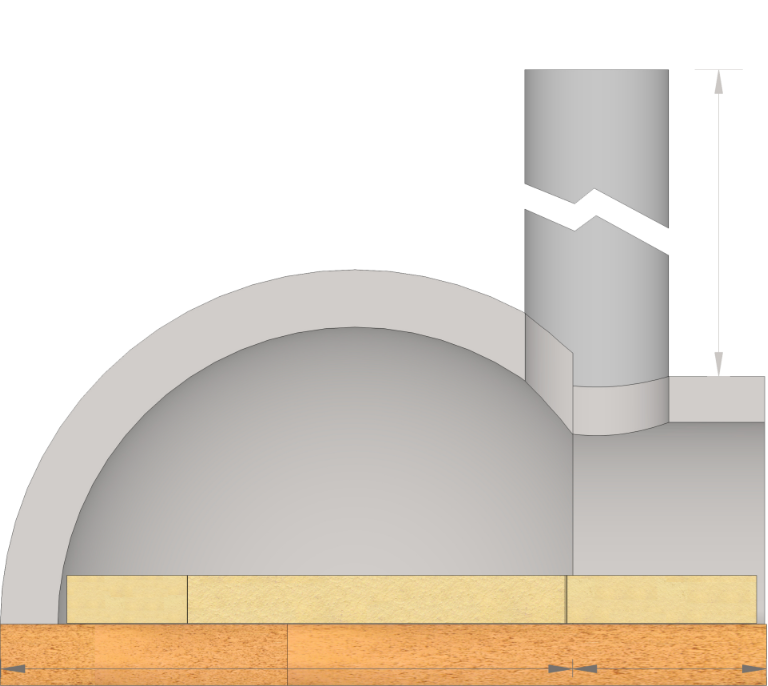

To build your pizza dome, use the refractory concrete mainly as a ramming mixture. However, some parts of the baking stove, such as the dome entrance and the smoke pipe collet, can also be cast. Homemade and screwed wooden forms are suitable as well as matching plastic containers. For optimum results, we recommend working with a concrete vibrator or concrete compactor.

How do I shape the refractory concrete?

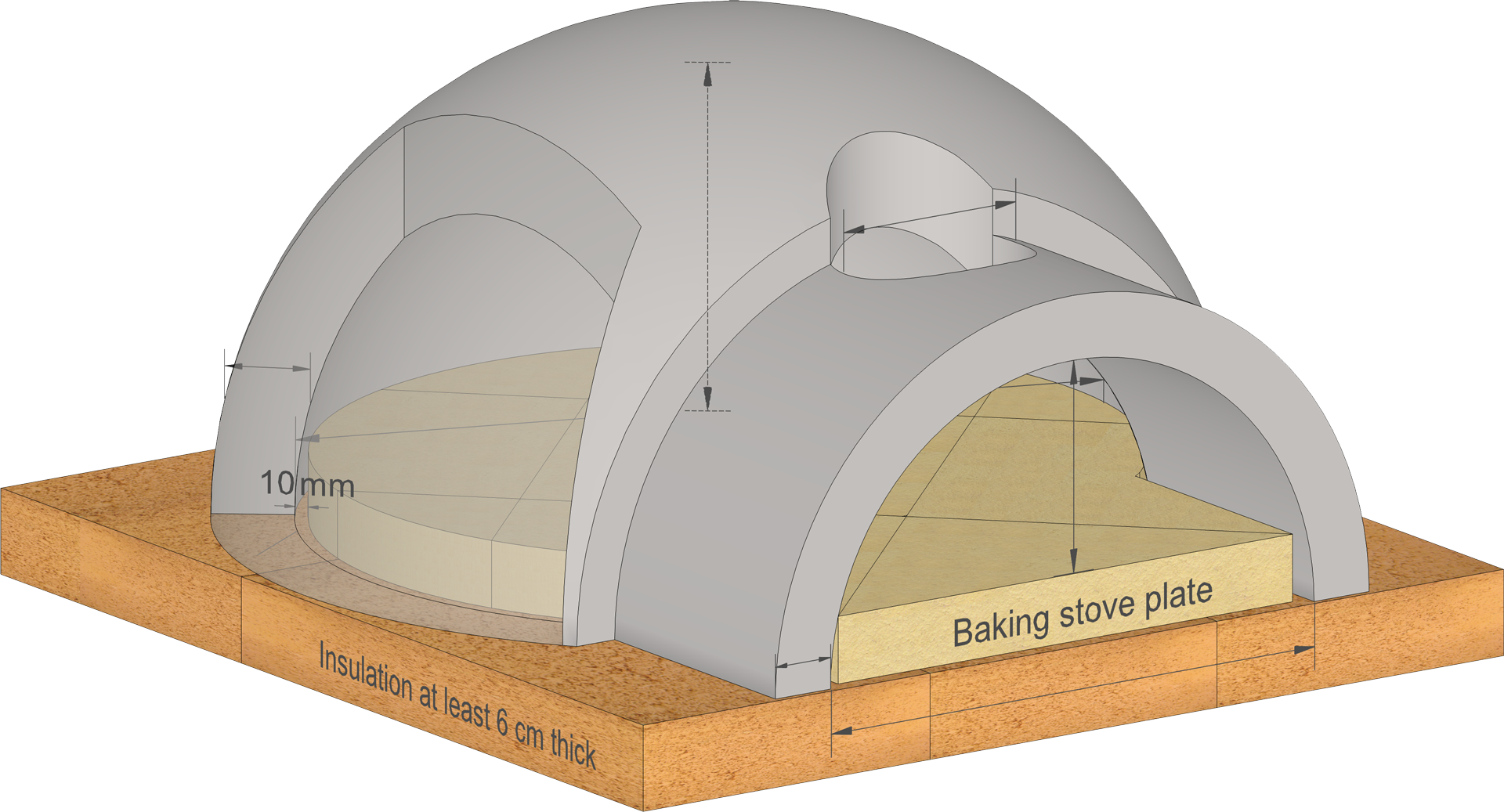

The amount of mortar required and the recommended wall thickness are shown in our dome calculator above. You should not build the dome any thinner, otherwise it will not be sufficiently stable. Also make sure that the thickness of the dome is even. You can easily check this with the help of appropriate stencils.

The dome is formed by mixing the refractory concrete as a ramming mixture and pressing it onto a shaping base. There are no limits to your creativity when choosing the shaping base: a pile of sand or an exercise ball pre-treated with spray grease, for example, are suitable.

What should I bear in mind to ensure that the pizza dome lasts?

To ensure that the mixture is easy to shape but not too moist, the amount of water should be as precise as possible and the mixture should be mixed as homogeneously as possible, preferably using a compulsory mixer. It is made even easier by adding a little Chamotte mortar C (approx. 10 – 15 %). This increases the stability and adhesion of the compound, making it even easier to apply.

Our refractory concrete is hydraulically setting, i.e. it hardens at ambient temperature and should therefore be processed within 30 minutes. Apply the individual layers of mortar quickly one after the other without allowing the surface of the finished layer to dry or even set. Otherwise, the layers may not bond sufficiently.

How do I let the refractory concrete harden?

The cement contained needs moisture to set completely. This means that the concrete should be protected from drying out too quickly by covering it with foil for the first two weeks and moistening it regularly.

The form is best removed after 24 hours. The refractory concrete is then fully hardened after 28 days. Until then, you should not light a fire in the dome, otherwise it may dry too quickly and form cracks.

Molded parts can be removed from the form after 12 – 18 hours and transported after 30 – 36 hours.

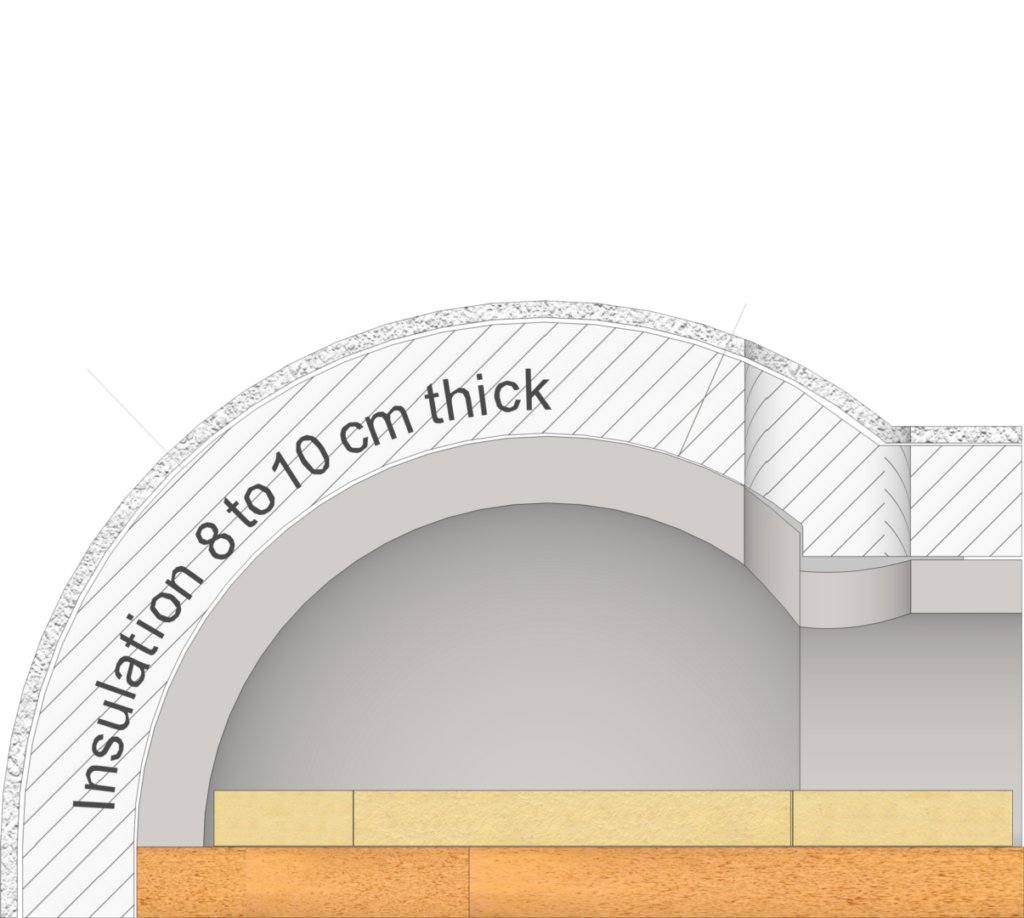

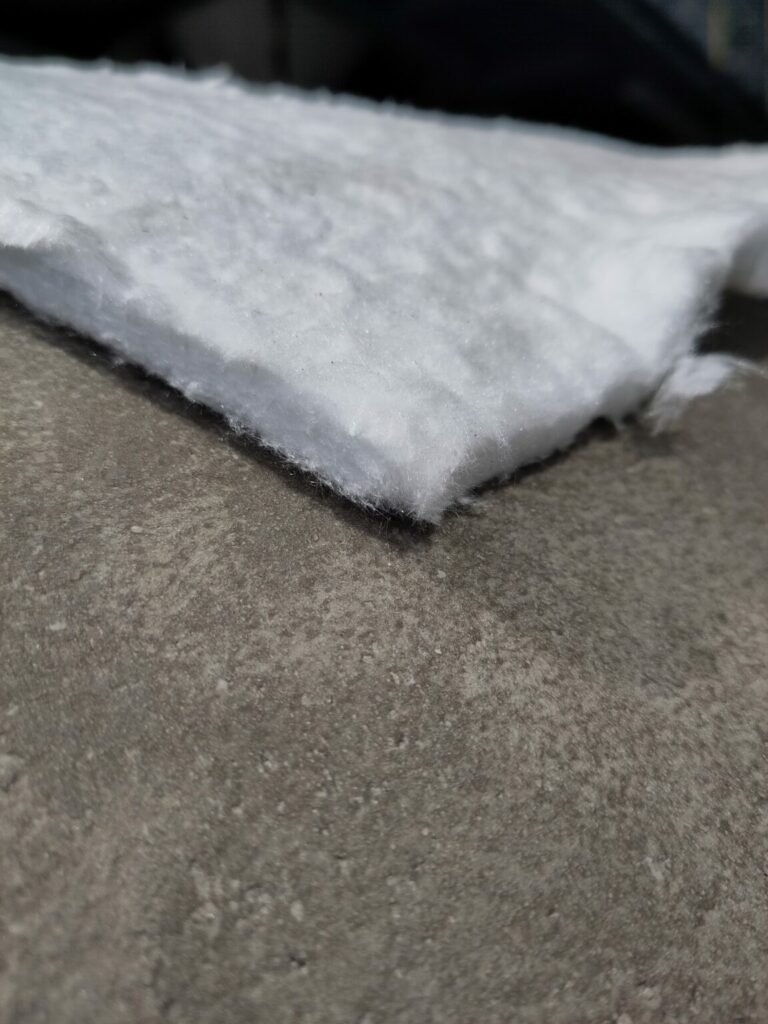

What is the best way to insulate my pizza dome?

Finally, all that remains to be done is to assemble all the parts with mortar and insulate and plaster the stove.

Choose a generous amount of insulation. The thicker the insulation, the longer it retains the heat and the more evenly the heat is distributed, which makes the dome more stable and durable.

How do I light my pizza dome for the first time?

To avoid cracking, the finished stove should be heated very slowly with a low flame the first time. This can be achieved by gradually increasing the amount of wood up to the maximum amount and ensuring that there is sufficient combustion air.

We recommend starting with 2 kg of wood, using thin logs at the beginning and spreading them widely over the baking surface. In this way you will achieve a flat fire that heats up the dome wall evenly. Then increase the amount of wood by 1 kg per day until the recommended amount of wood is reached.

Once the pizza dome is thoroughly hardened, you’re ready to go: the first pizza can be prepared!

Data sheet refractory concrete

You can download the data sheet with all technical details in our download area.

Do you still have

questions or suggestions?

We are happy to answer your questions and look forward to exchanging ideas.

Simply send us an email info@wolfshoehe.de.

And now: enjoy building you baking stove and your pizza!