How much CO2 did the production of my fireclay stove generate?

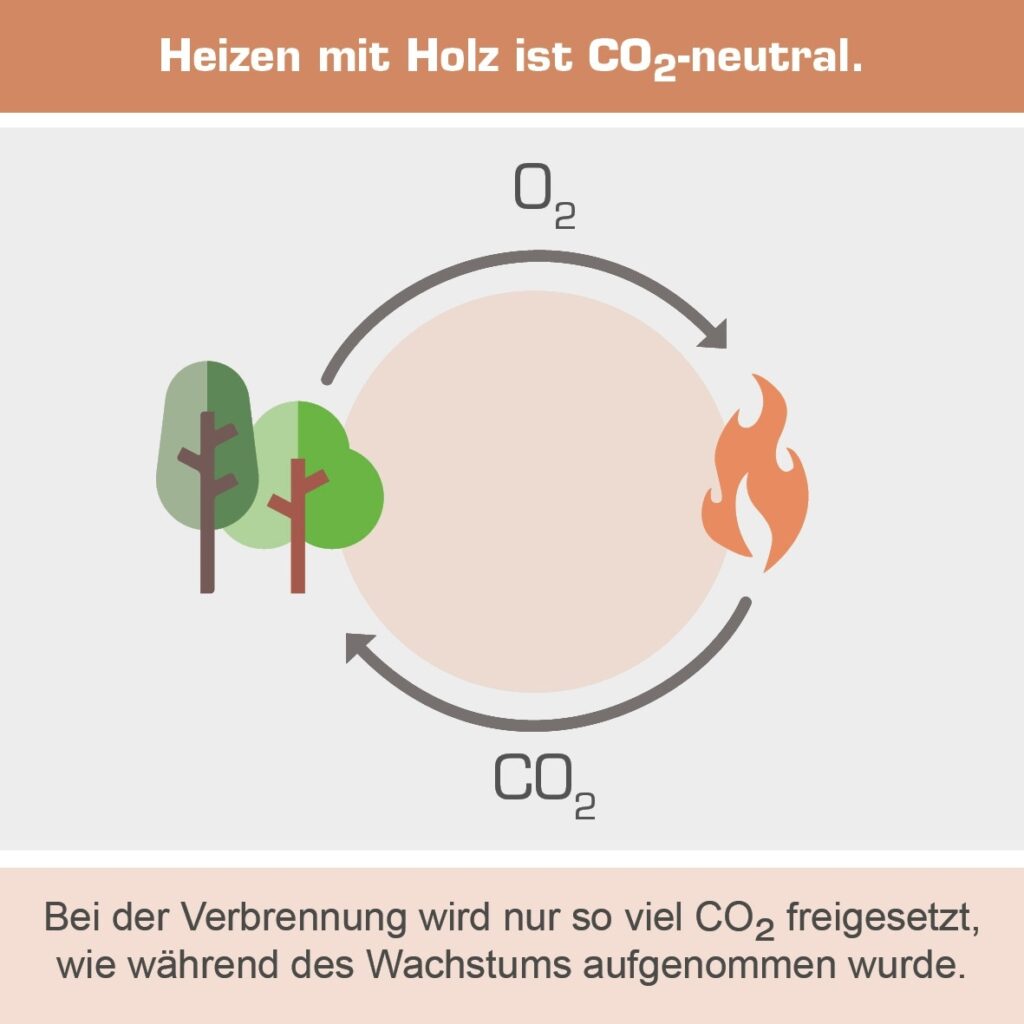

Heating with wood is CO2 neutral in itself.

Heating with wood is CO2 neutral. When wood is burned, only as much CO2 is released as the tree has absorbed during its growth and as much would have been released if the wood had been left to rot. If it is ensured that harvested wood is regrown to the same extent, which is a requirement in Germany, heating with wood can generally be described as sustainable.

But what about the upstream and downstream stages?

Anyone who takes a more than superficial look at the topic of “sustainability” also knows that there are also upstream and downstream stages of every product in addition to its actual use. If you really want to honestly assess the CO2 footprint of a product, these should also be considered and taken into account.

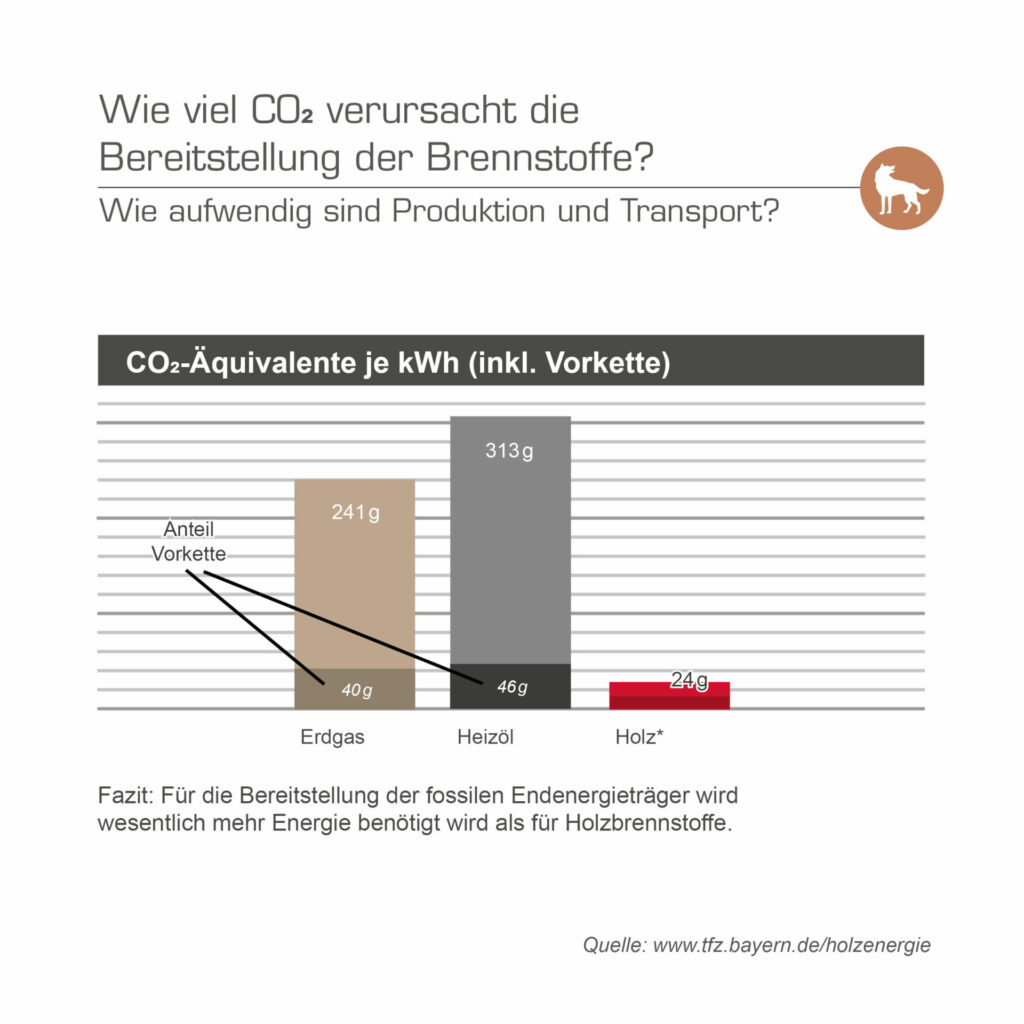

When heating with wood, for example, this includes harvesting the wood with gasoline-powered machines and transporting the wood to your home. It also includes the production of the fireclay bricks and other materials used in your stove.

So if you want to determine your personal CO2 footprint accurately, you should also take into account how much CO2 your fireclay stove has caused during production. We have the answer to this:

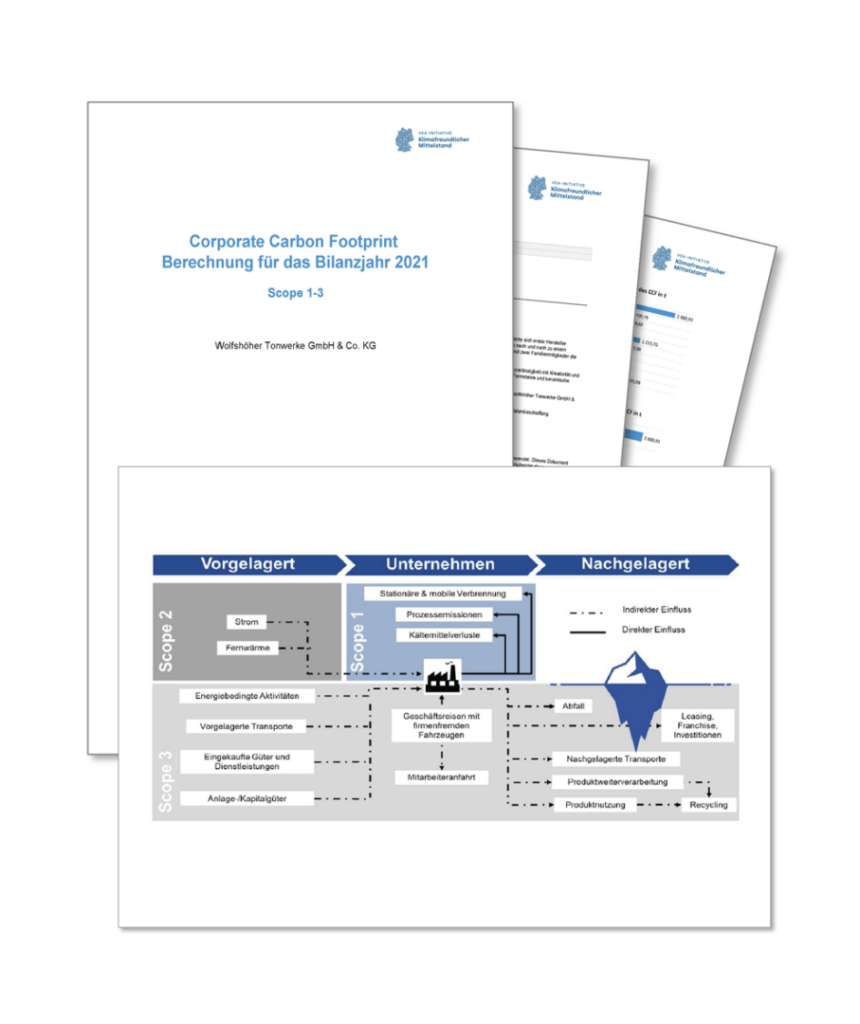

This is the method we used:

we have applied the most widely used international standard for calculating emissions (the GHG Protocol) to determine the amount of CO2e caused in the production of our fireclay.

CO2e stands for CO₂ equivalent and is a unit of measurement that includes the most important greenhouse gas caused by humans, carbon dioxide (CO2), as well as all other greenhouse gases and their greenhouse effect.

The GHG Protocol divides the emission sources to be accounted for into three scopes: Scope 1 covers direct emissions from combustion processes within the company. Scope 2 and 3 comprise the indirect emissions caused by external energy procurement (Scope 2) and all other upstream and downstream activities (Scope 3), e.g. the use of raw materials, logistics processes or downstream product use.

This analysis therefore considers virtually all aspects that should be included in an honest analysis. Nothing is excluded here, as is often done in many other places (keyword: greenwashing).

This very comprehensive examination of the production of our fireclay has shown:

for our chamotte, this results in a footprint of:

370 g CO2e per kg production volume

You can now use this factor to calculate the individual CO2e footprint of the fireclay in your wood-burning stove:

kg of fireclay used x 370 g CO2e = CO2e of your stove

Of course, your stove consists not only of fireclay, but also of other components such as the door, mortar or insulation. If you want to know exactly and also calculate the CO2e of the production of these components, you must ask the respective manufacturer. However, these components are less important than the fireclay used and can therefore be neglected or only estimated.

If you do not know how much fireclay is installed in your stove, ask your stove builder. He/she will be able to tell you.

Here is an example:

Our colleague Katharina’s water-bearing stove, which heats the whole house, is made of approx. 2 tons of fireclay. 2,000 kg fireclay x 370 g CO2e = 740 kg CO2e.

This does sound like much at first and is partly due to the fact that fireclay is produced using gas and requires very hot temperatures. However, this amortises very quickly during operation, because the stove produces hardly any CO2e during operation: only approx. 24 CO2e.

However, if Katharina were to heat her home with a heat pump, she would generate approx. 146g CO2e per kWh with the current electricity mix. Assuming a requirement of 10,000 kWh per year, the CO2e from production would be amortized after just one year.

Quite apart from the fact that the production of heat pumps is not CO2-neutral either. Depending on the refrigerant used, this can even have a major impact, especially again when it comes to the disposal. Fireclay bricks, on the other hand, consist of 100% natural raw materials. Their disposal after proper use does not harm the environment at the end of their life cycle.

Conclusion:

The production of the components of a wood-burning stove causes quite a bit of CO2e. The production of fireclay is energy-intensive and therefore leaves a certain footprint. However, as the operation of the stove is then almost CO2-neutral and as such a stove is generally very durable, the balance calculated over the entire service life is still unbeatable.

More blog posts

Video series: operating a wood-burning stove correctly

Heating with wood is sustainable – provided it is done correctly. We explain what you need to consider when heating with wood and how to operate a stove efficiently and with low emissions!

Do you already have a “stove certificate?”

The majority of emissions from heating with wood are caused by improper operation. This is why owners of wood-burning stoves need to be better trained. And this is exactly what the stove driving license does.

How harmful is heating with wood to the climate?

This question is repeatedly asked and controversially discussed. The Technology and Support Center in Straubing (TFZ) is now taking a stand on the most common theses.