- Precise dosing

- Homogeneous & stable mixture

- Efficient & flexible filling

Contract manufacturing and subsiding at Wolfshöhe

We are the chamotte specialists

For more than 160 years we have been committed to producing refractory fireclay of the finest quality. Whether chamotte, refractory mortars and masses, ceramic chimney pipes or shaped chamotte bricks for heating appliances. We have many years of experience in industrial heat treatment (calcination / sintering).

In our factory building for mixing and subsiding, we also offer contract manufacturing, contract mixing and contract filling of raw and building materials of this type or similar powdery to granular masses.

Do you require support and are you looking for a suitable business partner for your mixing and/or filling? Please do not hesitate to contact us.

Contract manufacturing and subsiding at Wolfshöhe

At the end of 2018, we put our new factory building for mixing and subsiding into operation. Here, we mix and fill our own mortars and masses and also offer contract manufacturing and contract filling of powdery to granular masses.

Do you require support and are you looking for a suitable business partner for your mixing and/or filling? Please do not hesitate to contact us.

Our modern factory building for mixing...

… is located on our factory premises in Neunkirchen am Sand near Nuremberg (in Franconia, Bavaria)

It has a production area of 900 m2 and includes:

- six main silos, each with a volume of 40 m³, which can be pneumatically filled via silo trucks

- various small silos, which can be filled via Big Bags or with bagged material – for dosing small and medium quantities

- feeders for the addition of grains prepared by us – e.g. of our own fireclay material

- several scales for precise weighing and dosing of the individual raw materials

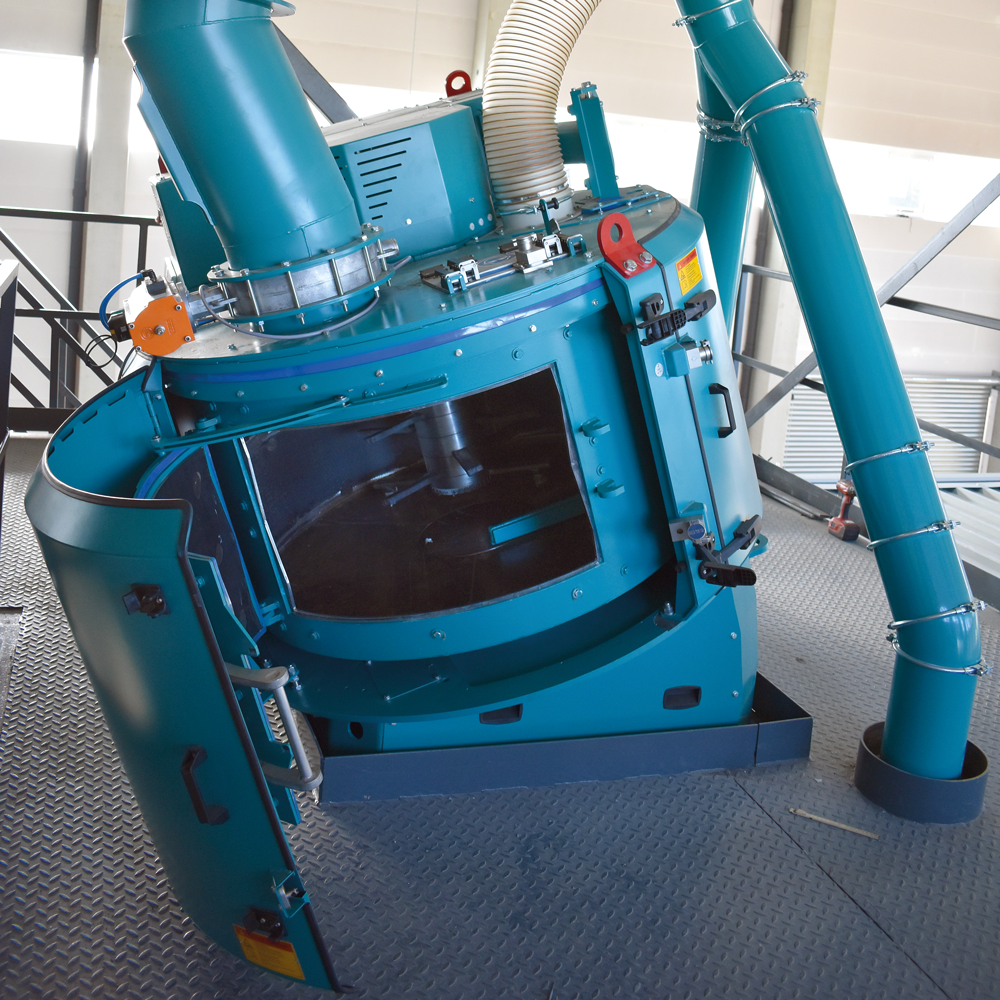

- a precision mixer for extremely homogeneous and stable mixtures

- a system for filling, decanting and packaging the masses

VIDEO: insight into our plant for mixing and subsiding

In this YouTube video, we take you on a virtual tour in order to show you our new factory building for mixing and subsiding.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationOur

services

Precise dosing

We weigh the raw materials with an accuracy of 0.05 % or 0.2 kg over several scales parallelly. If additives are required in particularly small concentrations, we add them via the manual addition.

Homogeneous stable mixture

After all raw materials have been added, they are transported from the hydraulic turning lift to the centrepiece of our plant: the intensive mixer. This mixer works with a rotating mixing tank and many optional mixing tools – for optimal homogenization! This innovative technology allows us to mix up to 400 litres in a very short time to a perfectly homogeneous and, above all, stable mass.

Efficient filling into buckets, sacks or Big Bags

Finally, we fill the mass with our filling machine – depending on the specifications into buckets, sacks or Big Bags of various container sizes – and this extremely efficiently with a capacity of up to 5 tons per hour.

Flexibel bei Auftragsgröße und -umfang

We offer the full package, from recipe development and optimization to homogenization and filling, or just individual services such as contract mixing or contract filling.

We are also happy to accept orders with a smaller volume. For example, would you like to outsource your manual filling and are looking for a suitable partner? Or are you an OEM looking for a service partner for external filling/packaging in smaller packaging sizes?

We are also the right service partner for this.

Our services

We weigh the raw materials with an accuracy of 0.05 % or 0.2 kg over several scales parallelly. If additives are required in particularly small concentrations, we add them via the manual addition.

After all raw materials have been added, they are transported from the hydraulic turning lift to the centrepiece of our plant: the intensive mixer. This mixer works with a rotating mixing tank and many optional mixing tools – for optimal homogenization! This innovative technology allows us to mix up to 400 litres in a very short time to a perfectly homogeneous and, above all, stable mass.

Finally, we fill the mass – depending on the specifications in buckets, sacks or Big Bags of different container sizes – and this with a performance of up to 5 t/h extremely efficiently.

We offer both the full package acting as a contract manufacturer with everything that goes with it, but we are just as happy to offer only any individual of these work steps.

On request, our service already starts with recipe development and recipe optimization. With our many years of expertise and our in-house laboratory, we are happy to support you in developing or maturing your product.

Do you have a powder mixture that has already been assembled but has to be homogenized in a stable way? Or a finished product that only needs to be filled or packaged into industrial or consumer packaging? We also offer the contract mixing and contract filling services separately!

And we are also happy to accept orders with a smaller volume. For example, would you like to outsource your manual filling and are looking for a suitable partner? Or are you an OEM looking for a service partner for external filling/packaging in smaller packaging sizes? We are also the right service partner for this.

Your products/industry

Dry materials such as powders, granulates, bulk goods and non-food stones are our core competence.

As a manufacturer of refractory mortars and masses for stove construction, we already have many years of experience in the processing and industrial heat treatment (calcination / sintering) of such masses.

In our mixing and filling plant, we also offer contract mixing and contract filling of raw and building materials of this type (such as rock flour, dry mortar, concrete, binding agents, sand, gravel, etc.).

No matter for which area of the building materials industry you are looking for a new supplier: please do not hesitate to contact us without any obligation!

Dominik Urban

Head of Sales

“Feel free to send us your recipe, a sample or the requirements for your final product!

I will be happy to provide you with advice and support, explain the options or give you a personal tour of our new facility.”

Your message to Dominik Urban