REMUS baking stove set - the construction is that easy

Our REMUS - cleverly designed

Our REMUS tunnel baking stove set has an intentionally compact design, can flexibly be extended if required, can also be used as a double-decker baking stove and is quick and easy to assemble.

Below we show you how easy it is.

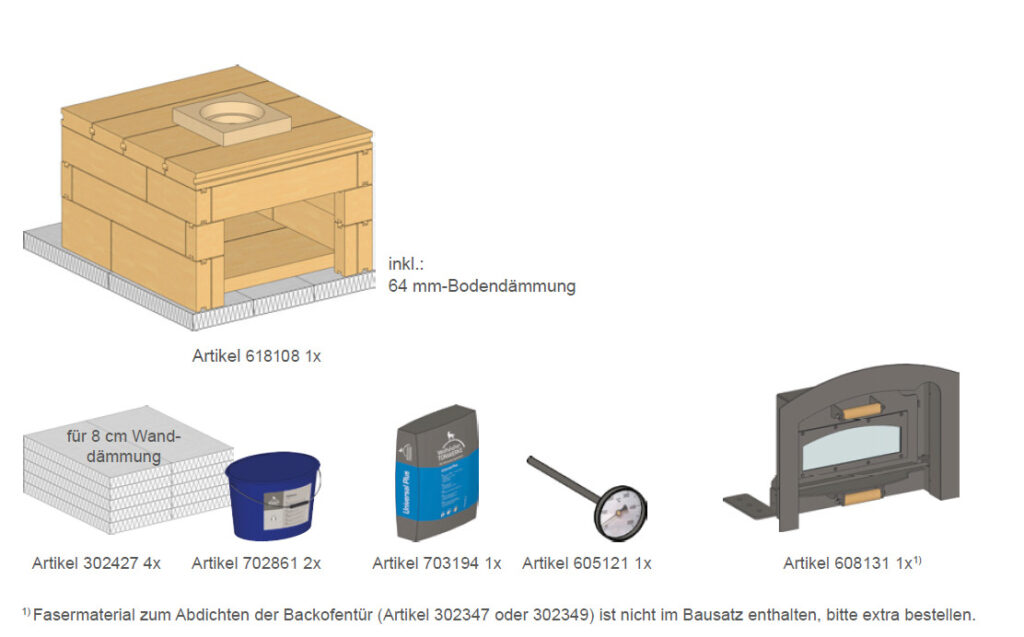

These items are included in our set:

In addition to the fireclay set, which consists of precisely prefabricated double-groove plates, the set includes the baking base, the smoke pipe collet, a high-quality baking stove door with viewing panel and bimetal dial thermometer, a sack of Universal Plus mortar, the wall insulation and the corresponding glue.

You will also need a sturdy, non-combustible base with ash tray, fibre paper to seal the ceramic and metal components, the chimney and chimney connection, a flue gas damper and an outer casing / walling.

Step 1

The first step in assembling the REMUS is to screw the baking stove door onto the base. To avoid damaging the door during construction, it is advisable to dismantle the door beforehand and only work with the door frame at first.

Step 2

The insulation plates are then laid first, followed by the baking plates. The baking plates are deliberately only laid on the insulation plates, not mortared, so that less tension is created later during operation. To protect the baking plates from dripping mortar, it is useful to cover them with paper or cardboard during the construction.

Step 3

In the next step, the first row of fireclay bricks with a joint thickness of between 2 and 5 mm is placed on the edge of the insulation plates. You should leave a gap of approx. 5 to 8 mm all around, i.e. no connection to the baking stove base, so that the material can expand later during operation. A ceramic fibre seal is used between the plates and the metal door to compensate for the different thermal expansion of the materials.

Step 4

The springs are then placed on the first row of the fireclay plates. After that, the second layer of fireclay bricks is laid. This second layer of fireclay bricks are the so-called support bricks. When fitting the support bricks, care must be taken to ensure that the smaller side is directed upwards.

Step 5

The deflection plates are then loosely placed on these support bricks so that approx. 9 cm remain open at the back. Another row of fireclay bricks and finally the cover plates follow. The cover plates are again fitted with springs and mortared in place.

Step 6

The flue pipe connection is installed in the front part of the baking stove top. As a result, the flue gases flow over the entire surface of the deflection plates and can transfer a large proportion of their heat energy to the fireclay. It is particularly important to note that the connecting piece must not under any circumstances bear the weight of the chimney or the weight of the connecting piece to the chimney, as the construction is not designed for this. Instead, the chimney or the connecting piece should be supported by the outer wall via attached iron profiles.

Step 7

Finally, the baking stove needs to be insulated. To do this, the provide insulation plates are attached twice in an offset pattern all the way around. The plates are not attached directly to the fireclay side walls, but are simply glued together with the Didotect mortar with a minimal gap to the fireclay. This allows the fireclay inner core to expand independently. Once the insulation or the outer casing / walling has been completed, the baking stove door is finally reassembled. A ceramic fibre seal is recommended between the front wall and the frame so that the material can expand here and the construction still remains tight.

Now the baking stove just needs to dry thoroughly and the fun of baking can begin.

Video instructions for construction

Here we show all the steps again in a video:

The long version with all the details

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationThe short summary for anyone with prior knowledge

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationConstruction manuals for our REMUS models

You can find the construction manuals for our REMUS models in our download area.

You don’t have an account yet?

Then register here.

More blog posts

Wood-burning baking stove made of fireclay – the components

Which components are required when building a stove and what special technical features need to be considered? We will give you an overview below – from the foundation to the rain cover.

A baking stove for the elementary school in Neunkirchen am Sand

The elementary school in our home town had long wanted a baking stove.

Wood-burning baking stoves made of fireclay – planning & construction

For you as a stove fitter, baking stoves made of fireclay are an additional area of business. In the following, we show you what to consider regarding the planning and implementing.